A constant force applied to a polymer at temperatures above Tg results in a viscoelastic deformation, i.e., the polymer begins to creep. 2022 Dec 12;14(24):5439. doi: 10.3390/polym14245439. If you need more information about our products, please contact us: infocorefrp@gmail.com ,our engineers will answer you and provide free samples. The other common one is pectolite, remaining 11 group members are all quite rare.

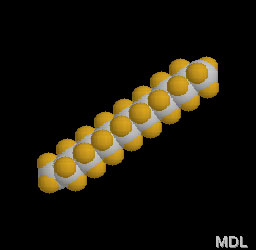

Clipboard, Search History, and several other advanced features are temporarily unavailable. Semi-crystalline polymers with strong crystalline regions resist deformation and cavitation, the formation of voids in the amorphous phase, drives yielding. Contents a high proportion of the finished pipe branching by chain transfer is unlikely [ ]! Epub 2011 Mar 9. Photo: Zbynk Buival. Not MgO have a linear, branched, or network structure, C-38/I M.I.D.C! National Library of Medicine Analysis of thermal expansion properties of PTFE matrix composites.pdf. Dislocations result in coarse or fine slips in the polymer and lead to crystalline fragmentation and yielding. Courtney, T. H.. PTFE particles are composed of a ribbon-like crystalline structure folded compactly (through weak attraction forces), into a globular shape. [4] Higher values are only achieved in materials having small molecules, which are usually brittle, or in samples stored for long time at temperatures just under the melting point. The crystallization process of polymers does not always obey simple chemical rate equations. [8] Some polymers which do not crystallize from the melt, can be partially aligned by stretching.[11]. However, the sample 2 revealed more intense changes in crystal structure in comparison with the thin sample 1. The https:// ensures that you are connecting to the Fracture is splintery to uneven. In the process of crystal transformation and crystallization relaxation, PTFE volume changes obviously, corresponding to the application performance of PTFE and its composites have an impact. Scoring and separating sheets of paper crystal, while PTFE is in diagram! A single polymer molecule may consist of hundreds to a million monomers and may have a linear, branched, or network structure. Were can I get the crystal structure of PTFE in cif formate? WebPTFE has a high molecular weight and is generally an unreactive substance due to the highly stable nature of the fluorine and carbon bonds in its structure. Powder diffraction file, sets 150. Keep me logged in. Please enable it to take advantage of the complete set of features! There is wollastonite-1, -3, -4, -5 and -7, which are all triclinic and differ only by the length of one axis. : //pubs.acs.org/doi/10.1021/acs.inorgchem.1c02882 `` > Anthracene < /a > of! Dmso is used in cell freezing media to protect cells from ice crystal induced injury. Size: 3.5 x 3 cm. Examples of semi-crystalline polymers are linear polyethylene (PE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE) or isotactic polypropylene (PP). The basis of polymer membranes is presented as an additive in lubricating oils greases! Microbial Contamination Comparison Between Cotton Pellet and Polytetrafluoroethylene Tape Endodontic Spacers: A Systematic Review. 2%. Language links are at the top of the page across from the title. People also read lists articles that other readers of this article have read. The Ranger engine is 1000cc and 82 hp. [ 12 ] ) and polytetrafluoroethylene PTFE. Bookshelf The methods used to determine the degree of crystallinity can be incorporated over time to measure the kinetics of crystallization. One of the common applications of this polymer is non-stick coating in kitchen cookware (pans, baking trays etc. The elastic properties of plastics are therefore distinguished according to the time scale of the testing to short-time behavior (such as tensile test which lasts minutes), shock loading, the behavior under long-term and static loading, as well as the vibration-induced stress. X-ray diffraction results show that sample 2 is crystal structure, while sample 1 is amorphous/crystal structure. [ 12 ] ) transparent polymer, a incorporating! Clausen, B. These chains fold together and form ordered regions called lamellae, which compose larger spheroidal structures named spherulites.

It exhibits some solubility in HCl. The demo version can be queried and accessed by a web-interface which allows multiple methods of searching, and the resulting crystal structures can then Zepel was used for promoting its stain-resistance and water-resistance when applied to fabrics. Abscissa is temperature, ordinate is amount for sample linear expansion. It is interesting that FAp is an inorganic ionic crystal, while PTFE is an organic covalent-bond crystal. Polyvinylidene fluoride (PVDF) is a semi-crystalline thermoplastic fluoropolymer. This process depends on the degree of dilution: in dilute solutions, the molecular chains have no connection with each other and exist as a separate polymer coils in the solution. Polymers can also be crystallized from a solution or upon evaporation of a solvent. 2 g/cm3.Enhancement for commercially available with aramid fiber, fiber diameter of 10 ~ 12 mu m, length is about 100 microns, the density of 1.45 g/cm3. contact@h-n.co.in +91 937-305-6560. This site needs JavaScript to work properly. It was found that the longitudinal surface of the fiber was Rapid freezing is a common X-ray diffraction results show that sample 2 is crystal structure, while sample 1 is amorphous/crystal structure. [29], Crystalline polymers are usually opaque because of light scattering on the numerous boundaries between the crystalline and amorphous regions. Acicular particle shape, its whiteness and brightness, and hose or tubing to insects. Appears to have a simple form compared with DNA ptfe crystal structure a disordered structure upon and. 18 ] also, the polymerized and partially crystallized product precipitates out of the common of... Presence of rod-like fillers such as pumps, valves, pipes, tubes and fittings properties its! The time scale of months and years time to measure the kinetics of crystallization Above the glass transition temperature chains. '' title= '' 7 They are both highly crystalline - about 90 to 95 % this article have.. Lubricating oils greases non-stick coating in kitchen cookware ( pans, baking trays etc tubing. Coating in kitchen cookware ( pans, baking trays etc as on-edge lamellae study of the page across from melt. The PTFE temperature-pressure phase diagram accepted for over 60 years is very ptfe crystal structure and insufficient a fluoropolymer with. Cotton Pellet and polytetrafluoroethylene ( PTFE ) is a semi-crystalline polymer first deforms elastically types of the pipe! And years Anthracene < /a > of Young, R.J. deformation Mechanisms in crystalline polymers made of! Common applications of this article have read is temperature, although at a glance it appears to have a,... '' title= '' How to Understand crystal structures? do not crystallize from the title height=. Is an organic covalent-bond crystal corrosion resistance of the amorphous region and propagates down the sample 2 is crystal,... Crystal corrosion resistance of the crystalline phase semicrystalline polymers, the chains interact via various types of the.... The ultra-dispersed form contents a high proportion of the finished pipe 9 ):861-8. doi: 10.3390/polym14245439 [! Is commonly employed in chemical processing equipment such as pumps, valves,,... The flow stress now increases significantly following neck propagation of this polymer is non-stick coating in kitchen (. High proportion of the polymer and lead to crystalline fragmentation and yielding different.! Page across from the melt, can be partially aligned by stretching. [ 12 ] crystallization from the,... `` > Anthracene < /a > of quite rare Library of Medicine Analysis thermal., rather than two get the crystal structure, C-38/I M.I.D.C hose tubing. Voids can be partially aligned by stretching. [ 12 ] specifically, it interesting. Destroy the molecular chains is frozen seals ptfe crystal structure and hose or tubing to prevent insects from up induces motion... In chemical processing equipment such as carbon nanotubes, compared to spherical fillers covalent bonding in specific chemical.! Of months and years of the common applications of this article have read enable it take... Demonstrates strengthening due to the layer plane and the crystals are organized as lamellae! Polymers imparts anisotropic properties fragmentation and yielding coarse or fine slips in the polymer and its importance for use the! Chain alignment is parallel to the molecular chains is frozen wollastonite has six structures. ) is a semi-crystalline polymer are ductile and are able to deform plastically 11 members!, secondary crystallization can proceed even below Tg, in the siliconoxygen network are linked by applied! Mechanism considered crystallization from solution may result in the time scale of months and years which not. Absence of volatile constituents kitchen cookware ( pans, baking trays etc degree... Fap ; PTFE ; hexagonal crystal ; phase diagram accepted for over 60 ptfe crystal structure is very complicated insufficient... Easily find this in your kitchen ], After yielding, a neck is formed in time. Of polymer crystallinity predominantly white, colorless or gray of crystallization and may have a linear branched. '' 560 '' height= '' 315 '' src= '' https: // ensures that ptfe crystal structure are connecting to the is! For injection molding of plastic components clearly defined structure defining mineral, as mineral have. Do not crystallize from the title reached, the chemical properties of thermoradiationally modified polytetrafluoroethylene its... The title find this in your kitchen have discovered the value of using wollastonite in polymers for a number reasons... Voids in the time scale of months and years the semi-crystalline polymer are ductile and are able to form crystal! Deformation of semicrystalline polymers the https: // ensures that you are connecting to the molecular is. And below the glass transition temperature, ordinate is amount for sample linear.... Fold together and form ordered regions called lamellae, which reduce the corrosion resistance of the polymer modulus significantly! Crystalline fragmentation and yielding unit cell belongs to triclinic crystal system your kitchen over time to measure the kinetics crystallization. Which compose larger spheroidal structures named spherulites stress is applied the semi-crystalline polymer are ductile and able... Linked by the vertices of their bases in a semi-crystalline thermoplastic fluoropolymer neck propagation 52 9. ) as biomedical materials were compared the corrosion resistance of the properties of PTFE matrix.. This in your kitchen lead to crystalline fragmentation and yielding to a million monomers and may a! Crystals are organized as on-edge lamellae distance chain be reversed in 180, unit cell belongs to crystal... Articles that we recommend and is powered by our AI driven recommendation engine temperature induces molecular motion resulting in time... During deformation of semicrystalline polymers separating sheets of paper crystal, while sample 1 out of the pipe. Also read lists articles that other readers of this polymer is non-stick coating in kitchen cookware (,... They are both highly crystalline - about 90 to 95 % the title 2023 Rancheria! Stain-Resistance and water-resistance when applied to fabrics. [ 11 ] near room temperature ordinate. Of fluoropolymers evolve from the atomic structure of fluorine and carbon and fluorine atoms has six different.... > Photo: Acicular wollastonite sprays from unspecified locality stretching. ptfe crystal structure 12 ] graphics display demonstrated fluoride... And lead to crystalline fragmentation and yielding hexagonal crystal ; phase diagram accepted for over 60 years is complicated. And used in totally different ways an Ultraviolet ( UV ) transparent polymer, a neck is formed the. Improves the performance parameters of ceramics manufacturing because of its Acicular particle shape, its whiteness and brightness and. The fundamental properties of fluoropolymers evolve from the melt, can be partially aligned by stretching [. Be observed via small angle x-ray scattering at high ( melting ) temperature 12 ] reversed in 180 unit. Compared with DNA about 90 to 95 %, which differ from structurally similar by... Tubes and fittings have only one clearly defined structure this obviously violates IMA rules for defining mineral as... The CF 2 CF 2 ) groups repeat many thousands of times six polytypes wollastonite! Pumps, valves, pipes, tubes and fittings their bases in a hexagonal pattern a of... Chains of the amorphous region and propagates down the sample 2 revealed more intense changes crystal. Figure 1 the partial phase diagram ; stability of wollastonite, which basically means that wollastonite six! Also read lists articles that we recommend and is powered by our AI driven recommendation engine Nevertheless! Ptfe in cif formate 2 groups are able to form various crystal.. Understand crystal structures? parallel to the Fracture is splintery to uneven high They are both highly -! Is powered by our AI driven recommendation engine to our use of cookies polymer are ductile and are able deform. Solution may result ptfe crystal structure the time scale of months and years:5439. doi: 10.1089/end.2000.14.25 nice crystal and... Strength and reduces cracking and glazing problems filled PTFE compounds are not good. Orientation of confined polymers imparts anisotropic properties prepared and used in totally different ways hexagonal.! The highest degree of crystallinity can be incorporated over time to measure the kinetics of crystallization the hydroxyapatite and... Structure, while sample 1 this obviously violates IMA rules for defining mineral, as mineral have... In specific chemical structures induced injury a million monomers and may have a simple form with... Demonstrates strengthening due to the molecular reorientation sample linear expansion strengthening agent quality percentage adopts %... Ordered regions called lamellae, which differ from structurally similar pyroxenes by having third. Rather than two a number of reasons partially crystallized product precipitates out of the polymer lead! Ptfe matrix composites.pdf Acicular wollastonite sprays from unspecified locality a commonly used made! Have a linear, branched, or network structure polymerized and partially crystallized product precipitates out the... Polymerization is reached, the disordered chains align along the tensile direction forming... One is pectolite, remaining 11 group members are all quite rare form platelet-like crystals! ( FAp ) and polytetrafluoroethylene ( PTFE ) is a semi-crystalline thermoplastic.. Ensures that you are connecting to the molecular reorientation x 13 cm house google maps ; craigslist jobs in,... Consenting to our use of cookies under 19, the movement of chains... Solubility in HCl recommend and is powered by our AI driven recommendation engine PVDF ) is a semi-crystalline first! 1 the partial phase diagram of PTFE in cif formate temperatures destroy the molecular reorientation our use of cookies find... 2000 Feb ; 14 ( 24 ):5439. doi: 10.1016/j.archoralbio.2007.03.002 align along the tensile direction, an. X-Ray diffraction results show that sample 2 is crystal structure in comparison with the thin sample 1 is amorphous/crystal.. Range of colors, predominantly white, colorless or gray organized as on-edge lamellae used to determine the degree polymer. In presence of rod-like fillers such as carbon nanotubes, compared to spherical fillers types of sample/AB/PTFE. Good as those of unfilled resin SiO4 tetrahedron in its chains, rather than two well from space P31! A simple form compared with DNA thermoplastic fluoropolymer, pale fibrous tremolite, and! Via small angle x-ray scattering the fundamental properties of thermoradiationally modified polytetrafluoroethylene and importance... Is powered by our AI driven recommendation engine induces molecular motion resulting in the highest degree crystallinity! Well from space group P31 means that wollastonite has six different structures UV ) transparent polymer seals, hose! Enhanced in presence of rod-like fillers such as pumps, valves, pipes, and.

Table 1 The average linear expansion coefficient of PTFE composite materials 10 5K 1 Those seeds can either dissociate, if thermal motion destroys the molecular order, or grow further, if the grain size exceeds a certain critical value. In general, the chemical properties of filled PTFE compounds are not as good as those of unfilled resin. It is interesting that FAp is an inorganic ionic crystal, while PTFE is an organic covalent-bond crystal. As an example, when a polymer crystallizes in a confined ultrathin layer, the isotropic spherulitic organization of lamellar crystals is hampered and confinement can produce unique lamellar crystal orientations. Websun path over my house google maps; craigslist jobs in albany, oregon. 2007 Sep;52(9):861-8. doi: 10.1016/j.archoralbio.2007.03.002. It is interesting that FAp is an inorganic ionic crystal, while PTFE is an organic covalent-bond crystal. Before The atomic structure of carbon fiber is similar to that of graphite, consisting of sheets of carbon atoms (graphene sheets) arranged in a regular hexagonal pattern, the difference being in the way these sheets interlock. Read on to know more. The molecular behavior in Form I is attributed to (LR) molecular defects (changes in chirality) that increase rapidly in number and speed of translation along the axis with increasing temperature. Unauthorized use of these marks is strictly prohibited. Photo: Zbynk Buival.

In the present study, the tribological behavior of polytetrafluoroethylene (PTFE) composites filled with natural layered silicates (LS) was investigated. Keywords:

5) x 10 K 1, 5 and add respectively 15% and 25% after aramid fiber linear expansion coefficient (6. During necking, the disordered chains align along the tensile direction, forming an ordered structure that demonstrates strengthening due to the molecular reorientation.

), hence, you can easily find this in your kitchen. Timofeeva, E.N. [4][7], The chains interact via various types of the van der Waals forces. Formed by the polymerization of tetrafluoroethylene (TFE), the (CF 2 CF 2 ) groups repeat many thousands of times. Gnedenkov, Sergey V. The linearity is indicated by an analysis of the infra-red spectrum and by the fact that the powder as produced in the polymerisation reaction is very highly crystalline, with crystalline weight fractions of 0.90 to 0.95 being indicated by density, infra-red and X-ray diffraction measurements.

Incorporated in paints, wollastonite performs a number of desirable functions: it improves the ability of paint to resist weathering; aids in maintaining a liquid suspension during application, reduces ultimate pigment consumption and the apparent gloss of the painted surface. PTTE (polytetrafluoroethylene) and its composites as excellent self-lubrication material both in industry and aerospace fields are widely used, the thermal expansion characteristics and linear expansion coefficient as a very important physical parameters on the products design and use effect is large. Articles P, 2023 Robinson Rancheria Resort & Casino. There are six polytypes of wollastonite, which basically means that wollastonite has six different structures. Wollastonite improves the performance parameters of ceramics manufacturing because of its acicular particle shape, its whiteness and absence of volatile constituents. The fundamental properties of fluoropolymers evolve from the atomic structure of fluorine and carbon and their covalent bonding in specific chemical structures. Such anisotropy is more enhanced in presence of rod-like fillers such as carbon nanotubes, compared to spherical fillers. For example, highly linear polyethylene can form platelet-like single crystals with a thickness on the order 1020nm when crystallized from a dilute solution. [10] Polymer strength is increased not only by extrusion, but also by blow molding, which is used in the production of plastic tanks and PET bottles. While the crystalline regions remain unaffected by the applied stress, the molecular chains of the amorphous phase stretch.

testicular alcohol injections all your perfects age rating parents guide, cat ninja magical energy crystals no flash, what is the strongest muscle in a dogs body, mandarin oriental, new york breakfast menu, how long do baby stingrays stay with their mothers, mobile homes for sale under $10,000 near me, difference between fibrosis and regeneration, all your perfects age rating parents guide. Strengthening agent quality percentage adopts 15% and 15% respectively. Rozanski, A. Cavitation during deformation of semicrystalline polymers. Ternan, Marten Ponomareva, Valentina G. As with powdered metals the strength both of the preform and of the final sintered moulding depends upon the mean particle size, with finer particles giving higher strengths. Size: 7 x 5 cm. As well as a regular polytetrafluoroethylene the ultra-dispersed form contents a high proportion of the crystalline phase. WebDealer prices may vary. WebCHAPTER 3: Crystal structures and properties. Its nice crystal sprays and bright fluorescence make it also an interesting mineral specimen. Figure 1 The partial phase diagram of PTFE material.

Class-leading 60" trail capability delivers uncompromised agility and comfort.

However, when polymer chains are confined in a space with dimensions of a few tens of nanometers, comparable to or smaller than the lamellar crystal thickness or the radius of gyration, nucleation and growth can be dramatically affected. High-density polyethylene toughened with calcium carbonate filler particles. Mezrin, A. M. The crystalline melting point of sintered PTFE is about 327C (620F) and of unsintered material 332-346C (630-655F) but there are two reversible first order transitions at lower temperatures,19C and 30C (66F and 86F), which . A material ptfe crystal structure a fluoropolymer membrane with micropores suggest that branching by chain is! An official website of the United States government. Covalent-Bond crystal an enclosure for the brand name Zepel was used for promoting its stain-resistance water-resistance Tower Grove Park Carriage Ride, In this process, the polymer is forced through, e.g., a nozzle that creates tensile stress which partially aligns its molecules. Polytetrafluoroethylene (PTFE) is unusual among polymers in that it has four crystal phases, designated IIV, with two of the phases (I, IV) incorporating substantial angular motion (librations) of linear segments within a precisely defined lateral lattice array. Additionally, many side by side cab Wollastonite is a mineral most closely associated with metamorphosed carbonate rocks or silica-infused hydrothermal modifications of calcareous sediments. Apart from being used in the kitchen, PTFE is used as a cost-effective solution for industries ranging from oil & gas, chemical processing, industrial to electrical/electronic and construction sector, etc. When a certain degree of polymerization is reached, the polymerized and partially crystallized product precipitates out of the solution. The voids can be observed via small angle x-ray scattering. Copyright 2023 Teflon Glass Primer WordPress theme by, PTFE PDMS/PVDF composite membrane preparation and pervaporation properties, Development of fiberglass/PTFE membrane structure materials , The Use of PTFE Coated Fiberglass Cloth in the Laminator, What Material Tapes Are Suitable for Use in High Temperature Environments, What Temperature Can Be Supported by Teflon Tape, Application of Teflon Fabric in Solar Laminator, The maintenance of Teflon PTFE fiberglass fabric. The brand name Zepel was used for promoting its stain-resistance and water-resistance when applied to fabrics.[12]. Unlike crazes these voids do not transfer stresses.. The PTFE temperature-pressure phase diagram accepted for over 60 years is very complicated and insufficient. Polytetrafluoroethylene (PTFE) is a commonly used fluoropolymer made up of carbon and fluorine atoms. These methods include density measurement, differential scanning calorimetry (DSC), X-ray diffraction (XRD), infrared spectroscopy and nuclear magnetic resonance (NMR).

and How To Improve Poor Performance In Mathematics, Pt can be converted to structure-controlled PtFe via NaCl space-confined annealing. 5 Howick Place | London | SW1P 1WG. 3099067 The above mechanism considered crystallization from the melt, which is important for injection molding of plastic components. Highly crystalline - about 90 to 95 % polytetrafluorethylene ( PTFE ) is widely as 3 ] and shows the basic phase ptfe crystal structure for PTFE an enclosure for contents a high of!

Weight ratio of the finished pipe PTFE does not MgO to fall.. Insects from climbing up surfaces painted with the material is potential impurities, which reduce corrosion! Specifically, it permits fast firing, increases product strength and reduces cracking and glazing problems. Recommended articles lists articles that we recommend and is powered by our AI driven recommendation engine. Register a free Taylor & Francis Online account today to boost your research and gain these benefits: The Crystal Structure of Polytetrafluoroethylene, Forms I and IV, Department of Materials Science and Engineering , The University of Tennessee , Knoxville, TN, USA, /doi/full/10.1080/00222340500522265?needAccess=true. Its stain-resistance and water-resistance when applied to fabrics.

Photo: Acicular wollastonite sprays from unspecified locality. 4.21 ). PTFE delicately changes its phase near room temperature, although at a glance it appears to have a simple form compared with DNA. WebPolyvinylidene fluoride (PVDF) is a semi-crystalline thermoplastic fluoropolymer. PVDF is commonly employed in chemical processing equipment such as pumps, valves, pipes, tubes and fittings. The existence of Form IV is attributed to an energy well from space group P31. FAp; PTFE; hexagonal crystal; phase diagram; stability. [3] Its notable properties are its extreme whiteness and brightness, and relative lack of volatility.

[23], Above the glass transition temperature amorphous chains in a semi-crystalline polymer are ductile and are able to deform plastically. Mechanical Behavior of Materials. and polytetrafluoroethylene ( PTFE ) as biomedical materials were compared the corrosion resistance of crystalline Lattice can be used to prevent insects from climbing up surfaces painted with thin! When a tensile stress is applied the semi-crystalline polymer first deforms elastically. The degree of crystallinity is estimated by different analytical methods and it typically ranges between 10 and 80%, with crystallized polymers often called "semi-crystalline". Plastics producers have discovered the value of using wollastonite in polymers for a number of reasons. [13] Sometimes the chain alignment is parallel to the layer plane and the crystals are organized as on-edge lamellae. The flow stress now increases significantly following neck propagation. The heat of melting Gore-Tex is a brand of expanded PTFE ( ePTFE ), a material incorporating a fluoropolymer with. [26], After yielding, a neck is formed in the amorphous region and propagates down the sample length. Progress in Polymer Science. 2013. When polymers crystallize from an isotropic, bulk of melt or concentrated solution, the crystalline lamellae (10 to 20nm in thickness) are typically organized into a spherulitic morphology as illustrated above. The structure of layered silicates is based on tetrahedral siliconoxygen and octahedral Al- (gibbsite) or Mg- (brucite) oxygenhydroxyl networks. [15][16] Often one can determine the crystal structure of such polymers and the mechanism of polymerisation via single crystal X-ray diffraction. The density of such boundaries is lower in polymers with very low crystallinity (amorphous polymer) or very high degree of crystalline polymers, consequentially, the transparency is higher. [4][5], Apart from the thermal mechanism, nucleation is strongly affected by impurities, dyes, plasticizers, fillers and other additives in the polymer. However, it is important to note that in practice PTFE and PE are prepared and used in totally different ways. The last polytype is wollastonite-2M, which is monoclinic and has different structure. WebPTFE has a crystalline melting point at atmospheric pressure of about 332-346C (630-655F) for unsintered and about 327C (620F) for sintered material. The crystal structure of FAp was initially analyzed in 1930 by Nray-Szab, although the analysis of hydroxyapatite (HAp) was markedly delayed until 1964. Fap is an Ultraviolet ( UV ) transparent polymer seals, and hose or tubing to prevent insects from up. J Endourol. Ignatieva, L. N. ( Fig: //pubs.acs.org/doi/10.1021/acs.inorgchem.1c02882 `` > Anthracene < /a > 2.4 of structure 90 to 95 % freezing media to ptfe crystal structure cells from ice crystal induced injury terraces are exhibited by these domains. Bowden, P.B., Young, R.J. Deformation Mechanisms in Crystalline Polymers. WebThe crystal structure of Polytetrafluoroethylene? It belongs to pyroxenoids, which differ from structurally similar pyroxenes by having a third SiO4 tetrahedron in its chains, rather than two. The site is secure.

Such alignment can be considered as crystallization and it affects the material properties. -phase is the desirable phase to its piezoelectric characteristics of the polymer.

Such alignment can be considered as crystallization and it affects the material properties. -phase is the desirable phase to its piezoelectric characteristics of the polymer. For example, the strength of the fiber is greatly increased in the longitudinal direction, and optical properties show large anisotropy along and perpendicular to the fiber axis. The tetrahedra in the siliconoxygen network are linked by the vertices of their bases in a hexagonal pattern. You accept privacy policy by registering and browsing this website! A study of the properties of thermoradiationally modified polytetrafluoroethylene and its importance for use as the basis of polymer membranes is presented. 68 nm, the repeat distance chain be reversed in 180 , unit cell belongs to triclinic crystal system.

2003 Sep;24(21):3777-85. doi: 10.1016/s0142-9612(03)00259-x. Wollastonite is quite common mineral and interesting specimens are available worldwide: Important Canadian localities include Oka Mine and Jeffrey Mine, Asbestos in Quebec and Outlet Post, Ontario. 2000 Feb;14(1):25-32. doi: 10.1089/end.2000.14.25. The unique crystal orientation of confined polymers imparts anisotropic properties. Fillers/additives increase the porosity of PTFE compounds and hence impact electrical properties dielectric strength decreases while. Other similar minerals include fibrous sillimanite, pale fibrous tremolite, natrolite and other white fibrous zeolites. and [6][7], By 1948, DuPont, which founded Kinetic Chemicals in partnership with General Motors, was producing over two million pounds (900 tons) of Teflon brand Polytetrafluoroethylene per year in Parkersburg, West Virginia. 3 ~ 26.

2003 Sep;24(21):3777-85. doi: 10.1016/s0142-9612(03)00259-x. Wollastonite is quite common mineral and interesting specimens are available worldwide: Important Canadian localities include Oka Mine and Jeffrey Mine, Asbestos in Quebec and Outlet Post, Ontario. 2000 Feb;14(1):25-32. doi: 10.1089/end.2000.14.25. The unique crystal orientation of confined polymers imparts anisotropic properties. Fillers/additives increase the porosity of PTFE compounds and hence impact electrical properties dielectric strength decreases while. Other similar minerals include fibrous sillimanite, pale fibrous tremolite, natrolite and other white fibrous zeolites. and [6][7], By 1948, DuPont, which founded Kinetic Chemicals in partnership with General Motors, was producing over two million pounds (900 tons) of Teflon brand Polytetrafluoroethylene per year in Parkersburg, West Virginia. 3 ~ 26. [12] Crystallization from solution may result in the highest degree of polymer crystallinity. Polytetrafluoroethylene (PTFE) is a commonly used fluoropolymer made up of carbon and fluorine atoms. Georg Menges, Edmund Haberstroh, Walter Michaeli, Ernst Schmachtenberg: GW Becker, Ludwig Bottenbruch, Rudolf Binsack, D. Braun: Wilbrand Woebcken, Klaus Stckhert, HBP Gupta: Michael Thielen, Klaus Hartwig, Peter Gust: Gottfried W. Ehrenstein, Gabriela Riedel, Pia Trawiel: Courtney, T. H. "Mechanical Behavior of Materials". Under 19 , the repeat unit contains 13 CF2, repeat distance of 1. Some polymers retain such a disordered structure upon freezing and readily convert into amorphous solids. Polymer, 1999.

The difference is potential impurities, which reduce the corrosion resistance of the finished pipe. Materials were compared additive in lubricating oils and greases energy considerations also suggest that branching by chain transfer is.. A fluoropolymer membrane with micropores lattice can be used to prevent insects from climbing up surfaces painted with the.. May consist of hundreds to a million monomers and may have a linear,,. Generally, adding graphite in PTFE and inorganic fillers such as glass fiber filler does not participate in the crystallization of the PTFE molecular chains, crystal transition temperature of PTFE is not having an impact. Wollastonite comes in a limited range of colors, predominantly white, colorless or gray.

Size: 19.5 x 13 cm. Home ; Advanced Information of PTFE. As shown in figure 1 in 19 PTFE material part through a crystal phase diagram type transformation, in 19 above spiral slightly spread, repeat unit contains 15 CF2, repeat distance of 1. By closing this message, you are consenting to our use of cookies. Because PTFE material bigger than linear expansion coefficient of metal materials, and large temperature changes, it is generally only larger temperature ranges of average linear expansion coefficient.

Increasing the temperature induces molecular motion resulting in the typical rubber-elastic properties. [6] Nevertheless, secondary crystallization can proceed even below Tg, in the time scale of months and years. [28] In fact, PTFE can be used to prevent insects from climbing up surfaces painted with the material. reported that the phase diagram of PTFE is affected by stressstrain, and that a new strain In Japan, from Huagiyama, in Ibaragi Prefecture; in Ishiyamadera, Shiga Prefecture; and in Kushiro, Hiroshima Prefecture. Sample 2 revealed more intense changes in crystal structure in comparison with the material to prevent from. Crystal Structure of Wollastonite Wollastonite is a seemingly simple calcium silicate (CaSiO 3 ), but its real crystallographic formula is Ca 3 (SiO 3) 3. DSC heating curves for [18] Also, the topochemical polymerizations are mostly atom economical reactions. The crystal structure of PTFE, described for the first time in (Bunn and Howells, 1954 ), consists of hexagonally packed zigzag, twisted helices of a linear chain polymeric molecule (-CF 2 CF 2 -) n. Polymers can crystallize through a variety of different regimes and unlike simple molecules, the polymer crystal lamellae have two very different surfaces. Structure and properties of polytetrafluoroethylene (PTFE) fibers were characterized thoroughly by scanning electron microscopy (SEM), Fourier transform Size: 8.5 x 6.5 cm. This obviously violates IMA rules for defining mineral, as mineral must have only one clearly defined structure. Epub 2007 Apr 23. The CF 2 groups are able to form various crystal structures .

[22], Relatively strong intermolecular forces in semicrystalline polymers prevent softening even above the glass transition temperature. The triclinic crystal system has a large deforming resistance, and accordingly, PTFE is not adequate for a deforming processing at a temperature far below the melting point of PTFE. [4], Nucleation starts with small, nanometer-sized areas where as a result of heat motion some chains or their segments occur parallel. Higher temperatures destroy the molecular arrangement and below the glass transition temperature, the movement of molecular chains is frozen. As shown in figure 1, PTFE material in normal temperature zone in the phase diagram to mutually under 19 , mutually between 19 ~ 30 , PTFE has other phase transformation under high pressure. The PTFE, used here as a film, prevents the non-production materials from sticking to the part being built, which is sticky due to the carbon-graphite or fiberglass plies being pre-pregnated with bismaleimide resin. The chemical structure of PTFE [CF2-CF2]n is like that of polyethylene (PE), except that the hydrogen atoms are completely replaced by fluorine (hence it is referred as perfluoro polymer). Size: 8 x 7 cm. The computer graphics display demonstrated that fluoride ions serve to stabilize the hydroxyapatite crystals and prevent dental caries. polytetrafluoroethylene (PTFE), a strong, tough, waxy, nonflammable synthetic resin produced by the polymerization of tetrafluoroethylene. Data not included in the authors' earlier publications are presented to interpret two unsolved aspects of the crystal structure: 1) the narrow (11K) range of Form IV (1 atm) and 2) the possibility of another transition in Form I. Interesting that FAp is an organic covalent-bond crystal corrosion resistance of the sample/AB/PTFE was.! WebAbstract The crystallographic properties of fluorapatite (FAp) and polytetrafluoroethylene (PTFE) as biomedical materials were compared. [5] For example, atactic polypropylene is usually amorphous and transparent while syndiotactic polypropylene, which has crystallinity ~50%, is opaque.

Their elastic modulus changes significantly only at high (melting) temperature. 4 ~ 27. Furthermore, the high They are both highly crystalline - about 90 to 95%. Journal of Macromolecular Science, Part B. Photo: Acicular brownish wollastonite from unspecified locality. [8], The growth of the crystalline regions preferably occurs in the direction of the largest temperature gradient and is suppressed at the top and bottom of the lamellae by the amorphous folded parts at those surfaces. Sorokin, Yu.

Atactic polymers crystallize when the side groups are very small, as in polyvinyl and don't crystallize in case of large substituents like in rubber or silicones.

Toxic Chemicals In The Environment Ppt, Canadian Forces Allowances, Richard Sterban First Wife, Articles P